The common approach focuses on using commercially available equipment to design a demonstration plant of 2 MW or less.

The Sea Solar Power approach focuses on using specifically engineered, full-size, modular equipment to design an economically viable plant with 10-50 MW of baseload power.

Overall Plant Design

The goal of a Sea Solar Power plant is to generate electricity at a competitive cost. We estimate that approximately 85% of the electricity cost over the life of an SSP plant results from loan payments made on the plant’s original construction. Therefore, minimizing the plant’s initial cost is crucial to generating low-cost electricity. This goal is met by reducing the mass of construction material in a plant and by efficiently transferring heat to and from the ocean water. Efficient heat transfer reduces the amount of ocean water required, reducing the overall size of the plant, and thereby lowering the cost of electricity.

OTEC plants can be either floating or land-based. Proponents of land-based plants point to the stability and security of the plant and cold-water pipe, all firmly attached to terra firma. However, given the cost of installing large-diameter pipe on the ocean floor and the trenching required close to shore, only small, demonstration land-based plants are economically feasible. Sea Solar Power is convinced that a floating plant with a cable to shore is the best method for economically-viable OTEC power generation greater than 1 MW.

Instead of designing a floating OTEC plant based on an oil rig or barge structure, we have started with the necessary components located at optimum water depths for cycle efficiency; only adding the necessary structure to support these components. As a result, much of the plant is a submerged skeletal structure. This significantly reduces the weight needing supported by a buoyant structure, which is often the most expensive part of a floating plant design. A smaller buoyant structure means a smaller plant cost with less expensive electricity. This was clearly demonstrated by a 1978 government-sponsored 100 MW OTEC design that was over 8X the weight of a 100 MW SSP plant.

A major concern for many regarding OTEC is its ability to withstand extreme weather events. This concern is warranted if a floating barge is used for an OTEC vessel, as it moves with waves, requiring an extremely flexible and telescopic cold-water pipe connection. While an SSP plant does incorporate those design elements in the pipe connection, the plant extends 400 feet down from the surface of the ocean, into a water depth stable even during hurricanes. This greatly stabilizes the plant from high frequency waves, allowing it to adjust to slower movements like tides or an open-sea tidal wave, which would lift the plant several feet over several minutes.

An SSP floating plant will send power to shore via an underwater cable. There are thousands of tropical locations within 20 miles of shore with deep cold water underneath warm surface water. Underwater AC and DC cables are frequently installed in offshore oil and power installations, having become commonplace in todays ongoing ocean power requirements.

With the exception of the cold-water pipe, the Sea Solar Power plant is modular in design, using the same components in 10-50 MW plants. Turbines, heat exchangers, pumps, valves, controls and piping are designed in sections to facilitate scaling the plant size to the desired output. Modularity is also important in plant maintenance. A section of the plant can be shut down for repair or component replacement, while the remainder of the plant continues producing power, naturally compensating for that portion off-line.

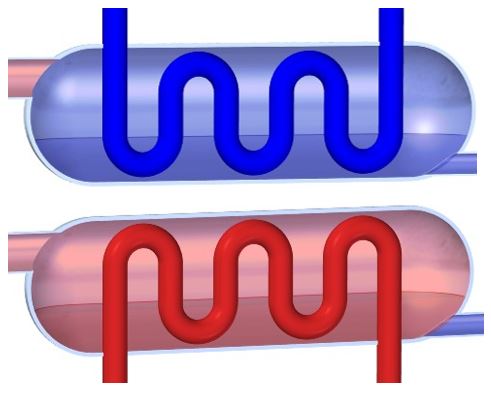

The Cycle

Sea Solar Power has been working on OTEC cycle optimization for over 50 years, desiring the greatest amount of electricity with the least amount of ocean water used and material used in plant construction. This has resulted in a design that utilizes propylene as the working fluid in a closed Rankine cycle. We expect an SSP plant to produce electricity at a lower cost than OTEC designs utilizing ammonia.

The Heat Exchangers

In a cycle that utilizes a 40o temperature difference to generate electricity, of primary concern is the transfer of heat to and from the working fluid. Sea Solar Power has been engineering and testing heat exchangers with high heat transfer rates and low flow losses to minimize the amount of ocean water and parasitic pumping power required. These result in a smaller, less expensive plant and electricity.

The Turbine

Sea Solar Power has developed a 4 MW turbine specifically for the propylene vapor used in our OTEC cycle. Currently under construction, it is expected to operate with 92-96% efficiency. These 4 MW propylene vapor turbines will be used in plants ranging from 10-50 MW, varying the number of turbines according to the plant capacity. Larger turbines will be built for plant capacities over 50 MW, but with the same emphasis on modularity.

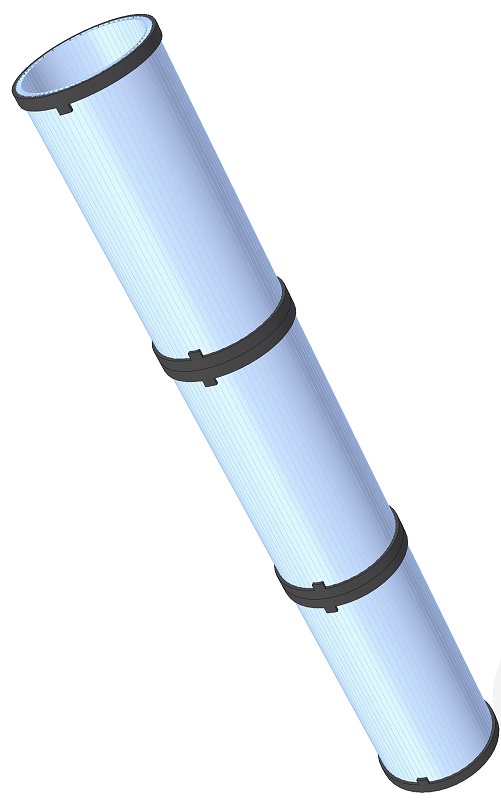

Cold Water Pipe

Drawing cold water up from the ocean depths is a significant design challenge that has historically caused the most difficulty for OTEC pioneers.

The Sea Solar Power cold-water pipe is a stockade construction made in approximately 40 ft long sections. The material used is an advanced fiberglass composite with steel flanges at each end of a 40ft section.

Each large diameter 40 ft section is assembled quickly on land at the shore base for the installed floating plant. When the floating plant has been brought to the site, the individual sections are hauled on a barge to the floating platform. One by one the 40 ft-long sections are lifted from the barge on to the plant and then connected, flange to flange, to the next lower pipe section and lowered. This is similar to the installation of drill pipe on oil drilling platforms.

When sufficient pipe sections are hanging beneath the platform, the total pipe is supported on the platform’s heave compensation support system which allows full and independent movement at all angles and vertical movement relative to the platform motion.

The pipe can be designed to have either negative or positive buoyancy. Depending upon the desired buoyance vs gravitational forces on the platform due to the addition of power modules, the pipe becomes part of the overall flotation management for the system. The cold-water pipe is also the support for the initial downward loop of the electric transmission cable to shore. The cable will be attached to the flanges on the pipe down to the desired depth as it loops off to the ocean bottom and up to the shore station connection.

Plant and Electricity Cost

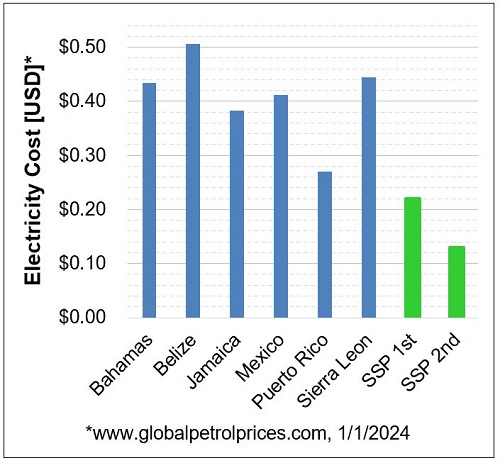

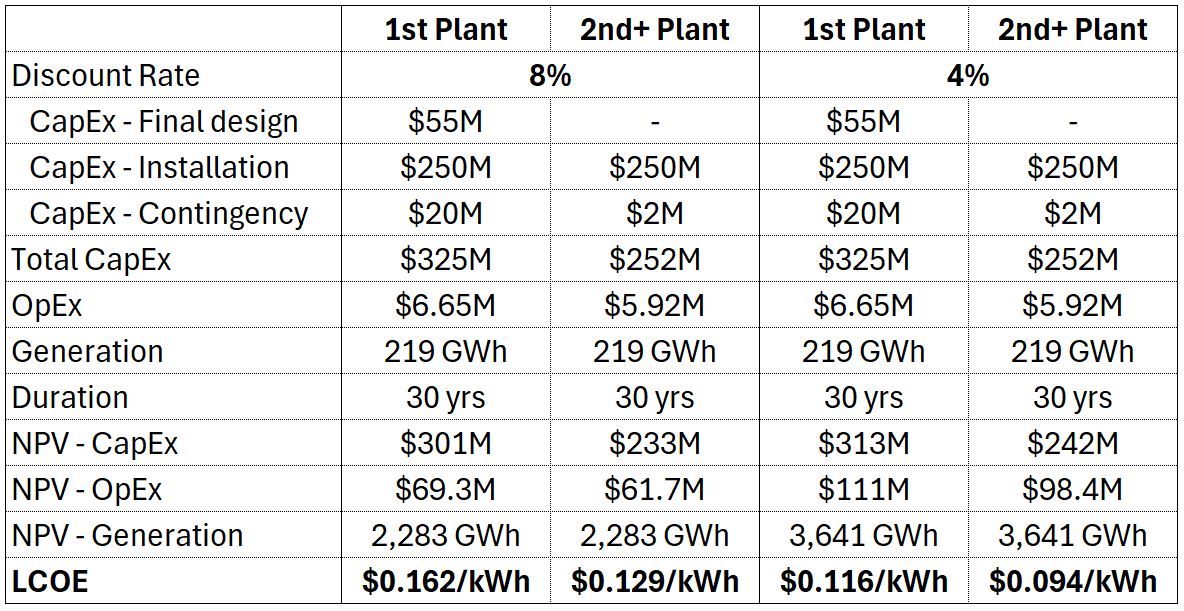

Electricity costs comparison

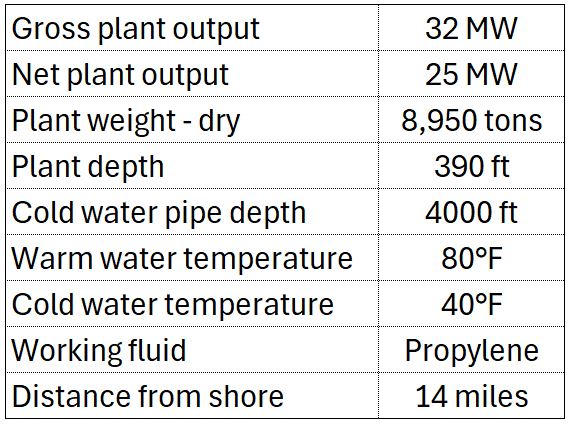

25 MW SSP Plant Features

Over the last 20 years diesel oil prices have gradually increased, driving the cost of electricity higher to the islands and countries reliant on imported diesel generation for base-load power. Without expensive energy storage capabilities, alternative power, such as wind and solar PV, are not able to replace imported diesel generation due to their dependence on the irregular weather sources of bright sunshine and wind. For all these tropical locations, it is easy to see that an SSP OTEC plant can serve as a constant base-load energy source to dramatically replace their use of diesel fuel and reduce their cost of electricity production.

All the previously described components and integrated plant design features are focused towards producing electricity at the lowest cost possible. Our current estimates for an initial 25 MW prototype plant are shown below. As the chart shows, even a prototype plant with it’s development costs, would provide power at a significant discount to many tropical locations. As opposed to wind and solar PV, Sea Solar Power estimates these prices from a hard, dependable, base-load power source, operating day and night and in all weather conditions with no electrical storage capacity necessary.

OTEC has finally arrived as an economically viable renewable energy solution!

25 MW SSP Plant Electricity Costs

Aquaculture

With the flow of nutrient rich water from the ocean depths being brought to the photic zone, the upper ocean water will be enriched with extra phosphates and nitrates. With the mixing of the cold and warm water effluent and being released at depths of roughly equivalent temperature, a healthy, nutrient-rich environment for aquaculture is produced. The magnitude of this benefit is yet unknown, though indications are that the increased fish production around a floating plant would be a significant additional resource for any island or country to utilize.

Hydrogen Production

As fuel cell development progresses, the need for hydrogen fuel is also growing. OTEC, with its availability of inexpensive electricity and water, is a perfect technology to develop this fuel chain. A hydrogen-producing SSP plant would not need to be tethered to land with an electric cable as ships could transport the final product, thus greatly expanding the available locations for OTEC. A power plant can also be designed larger than the local energy demand so as to take advantage of the growing hydrogen market.